- Continuous or pulsed operation

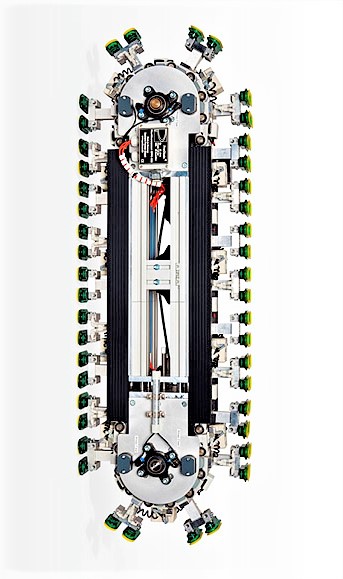

- Modular, standardized assembly

- Configurable Function Design

- Fast possibility of adjustment for product change

- High rate of feedt up to 3m/s and high acceleration .depending on the product

- Arrive punctually switching with ASi-Bus at all speeds

- Products profile and material independent transported in all positions

- Any combined assembly possibilities of.Pneumatic, Sensoric and Electronic

- Virtually wear-and maintenance-free operation

- High flexibility

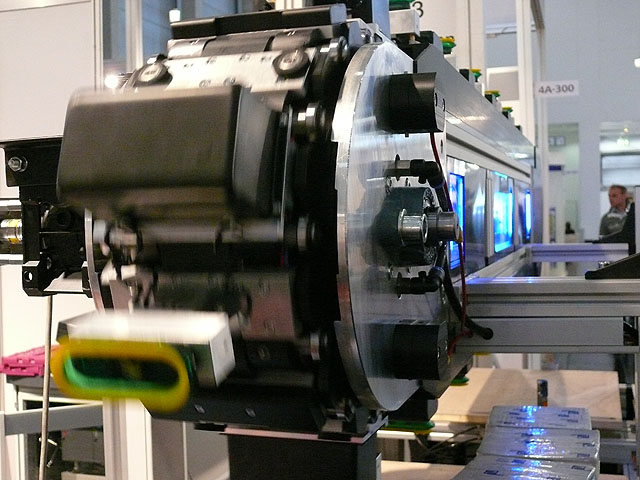

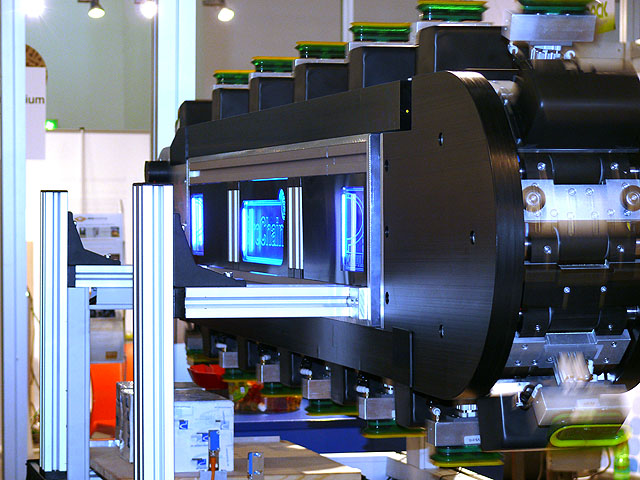

Circulating, intelligent chain system with energy as compressed air, electricity, and data

- Air pressure by rotary in the air pressure channel (up to 10 bar)

- Power supply (24 V DC) via slip ring contacts in line

- Data transfer via Asi-bus

Flexible execution of controlled functions at defined positions in circulation

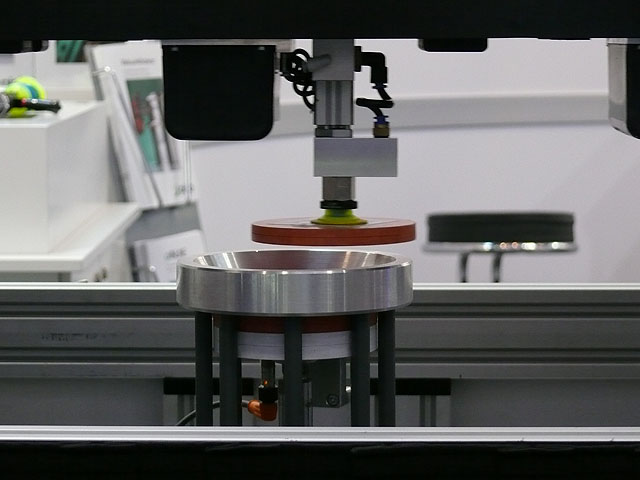

- Combined use of pneumatic products such as suction/gripper/cylinder

- Switching of actuators, solenoids, or e-drives

- Integrated sensors and signal transmission for monitoring functions

- Transport of various products regardless of what Surface / material / Geometry

- Positioning functions of collection, processing, packaging, etc.

- Stacking and unstacking

- Discharge / separation of parts

- Packaging applications for example Insert, Carton

- Palletizing e.g. Cartons, boxes

- Mount e.g. Paste, screws, mounting

- Printing

- Check e.g. Leak, visual inspection

- Output: 50 parts / sec or 3000 parts / min. (for example, at 60mm pitch, 40mm size pieces) other forms in consultation

- Max. speed: 2 - 3 m / s (target: 6 m / s)

- Conveyor Chain: Block or hinge chain

- Guideway: Roller or plain bearings

- Tracked: Standard: linear, curvilinear

- Chain pitch: Standard: 60 , 80, 100 mm or arbitrary

- Length: Optional chain division under

- Width: Standard 100 mm or in consultation

- Height: Depending on the chain division

- Mode: Continuous or pulsed

- Type of drive: Unlimited

- Protection: Up to IP65

- Control: ASi (A/B Slave´s, specification 2.1)

- Control interface: ASi bus coupler

- Max acceleration: In pulsed mode depends on the conveyed

- Repeatability: +/- 0,1 mm

- Ambient temperature: -5°C bis +50°C

- Operating pressure: 1 - 10 bar

- Pneumatic connection: Free choice, Flow-induced

- Air consumption: For each application

- Operating medium: Pressure air to the quality class DIN ISO 8573-1 Class 1-1-3

- Material: Aluminium, stainless steel or plastic

- Corrosion resistance: KBK class